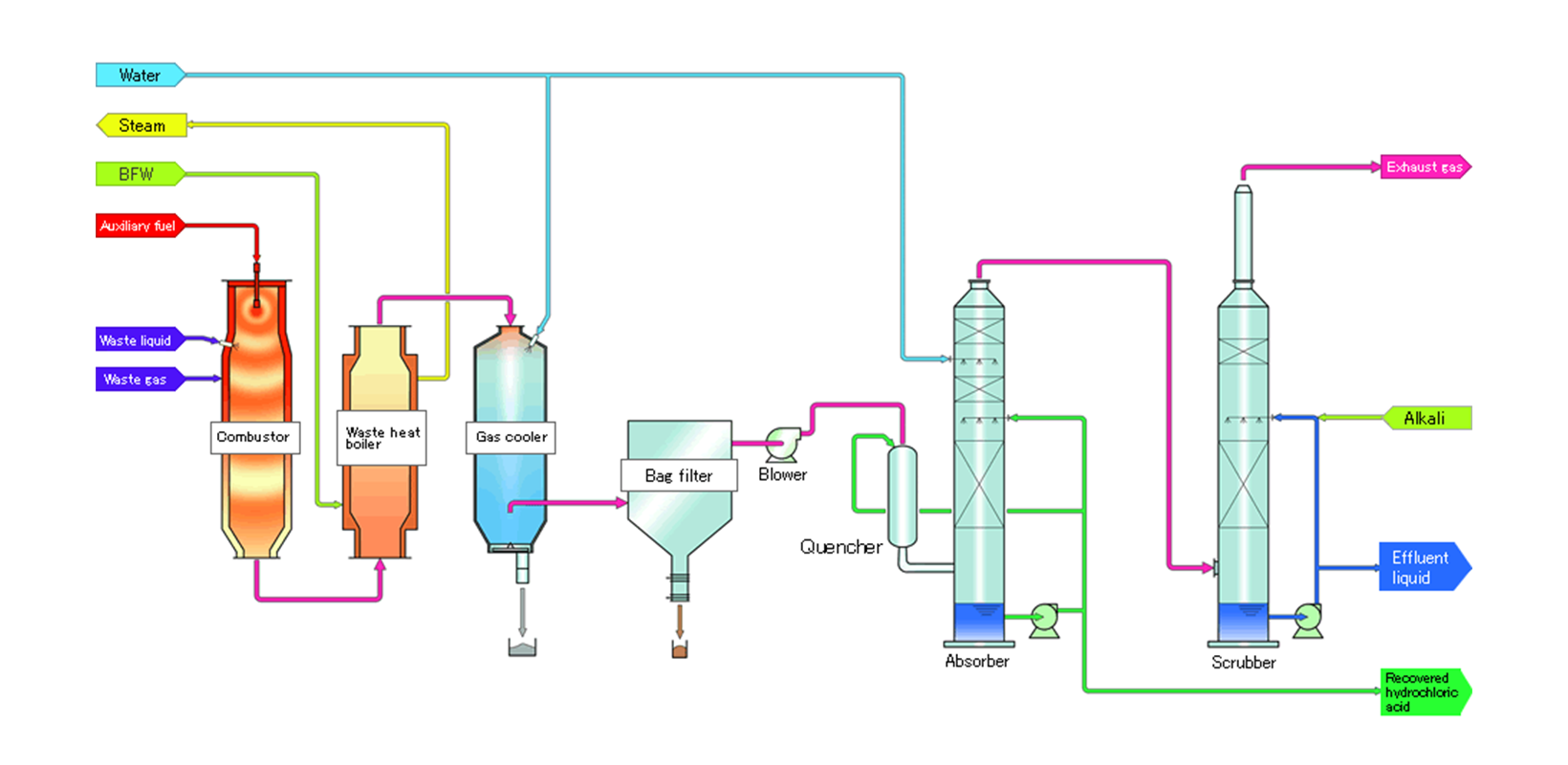

Hydrogen chloride recovery process

Treatment of waste liquid containing organic chloride compound

This process is that HCl which is formed by incinerating organic chloride compounds is recovered as HCl solution / gas.

Features

- Complete decomposition of organic compounds

- Efficient heat recovery from high temperature with boiler

- Recovered HCl concentration can be higher than azeotropic composition by adding stripper.

Application examples

- Waste gas/liquid of organic chloride compounds and organic silicate compounds.

- Pickling waste acid.

Examples

Chlorosilane waste liquid and gas

| Item | Waste liquid A | Waste liquid B | Waste gas A | Waste gas B | |

|---|---|---|---|---|---|

| Capacity | 270kg/h | 100kg/h | 640kg/h | 430kg/h | |

| High heating value | 26,000kJ/kg | 3,000kJ/kg | 8,000kJ/kg | 2,500kJ/kg | |

| Supply location | Burner | Furnace | Burner | Furnace | |

| Operating time | 24 hours continuous | ||||

| Combustion temperature | 1,200℃ | ||||

| Exhaust gas residence time | 2 seconds or more | ||||

| Combustion load | 13,500MJ/h | ||||

| Exhaust gas flow rate | 10,000m3/h (NTP) | ||||

| Effluent water flow rate | 2,000kg/h | ||||

| Recovered HCl concentration | 15wt% | ||||

| Recovered hydrochloric acid flow rate | 3,000kg/h | ||||

| Recovered steam pressure | 1.2MPaG(Saturated) | ||||

| Recovered steam flow rate | 2,000kg/h | ||||

| Exhaust gas | Dust | 80mg/m3(NTP) or less | |||

| NOx | 500mg/m3(NTP) or less | ||||

| SOx | 300mg/m3(NTP) or less | ||||

| HCl | 70mg/m3(NTP) or less | ||||

| Foot print | 35m × 25m × 20mH | ||||