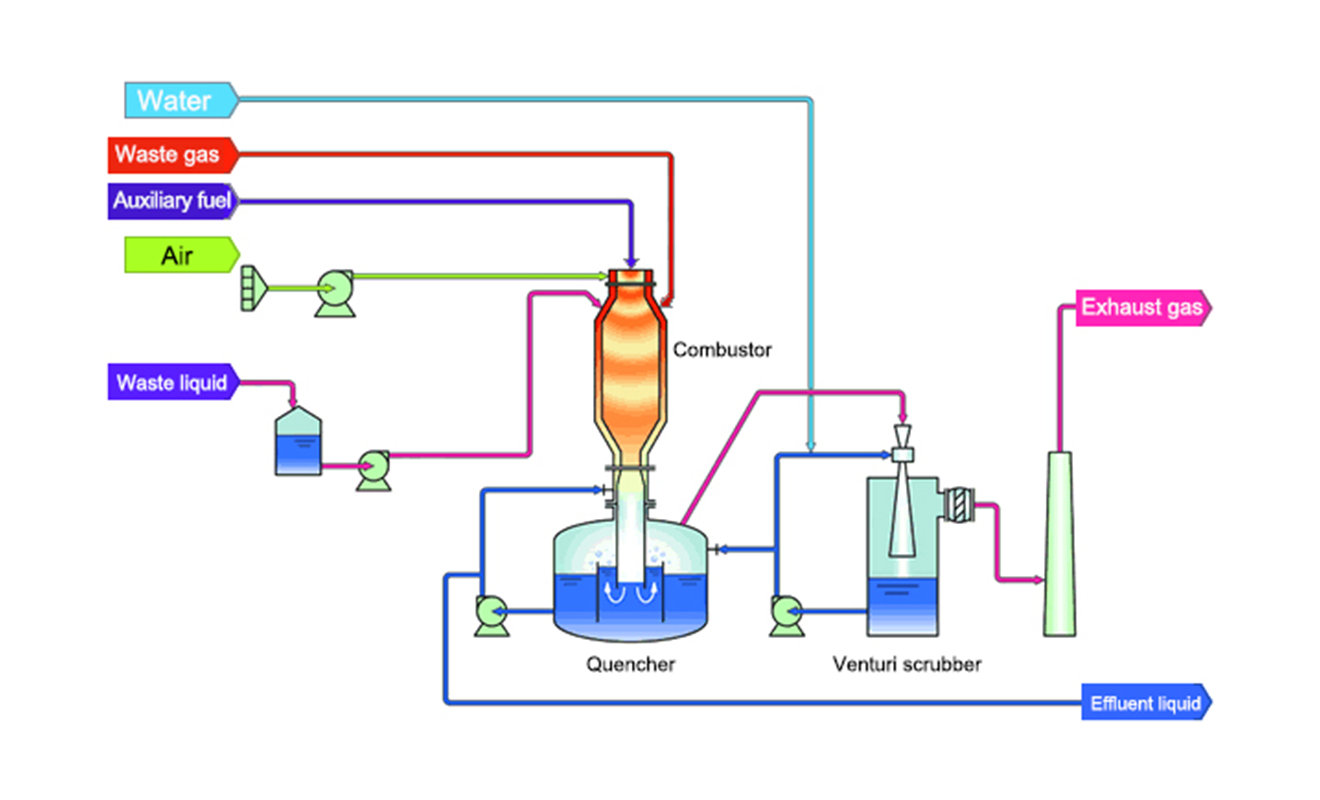

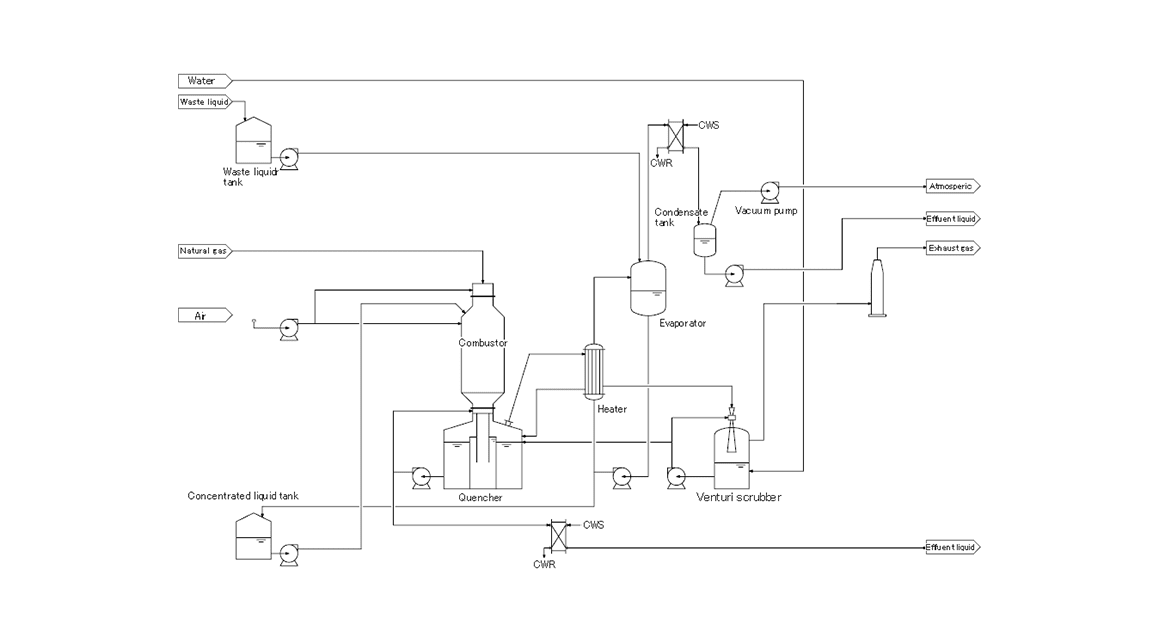

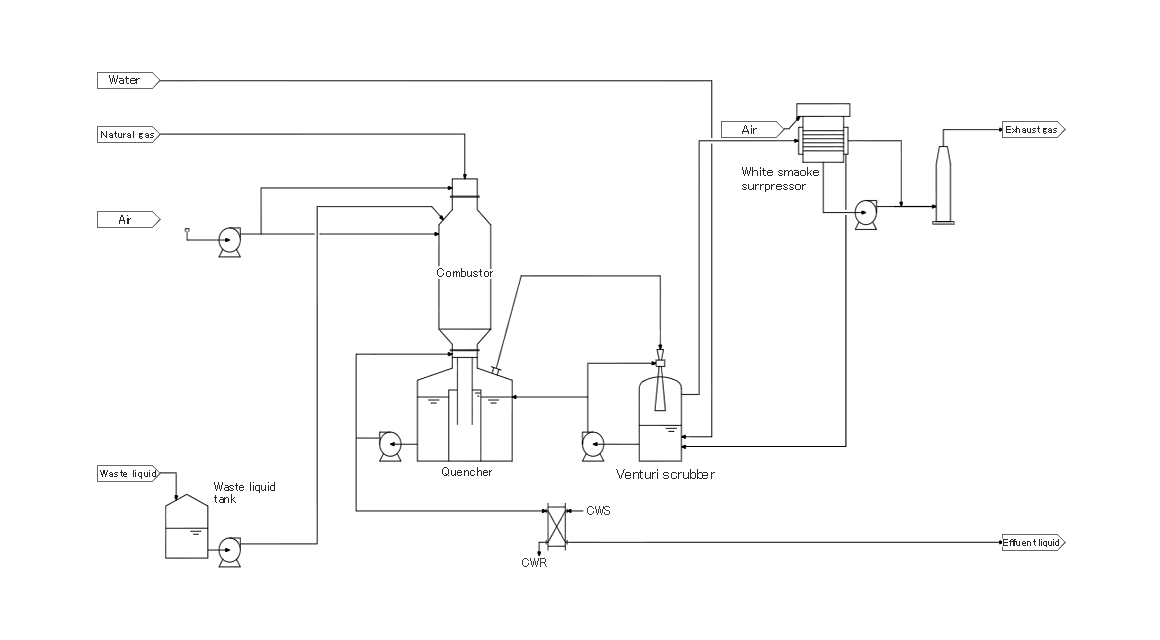

Waste liquid incineration / Submerged combustion system

Treatment of waste liquid containing alkali metal compound and high COD substance

Features

- Operation of waste liquid containing alkali metals without clogging

- Complete decomposition of organic matter and high COD substance

- No producing dioxins by quenching system

- Simultaneous treatment of waste liquid oil and gas

- Non-catalytic NOx decomposition

Application examples

- Waste liquid/gas from manufacturing process of chemicals, agrochemicals, organic pigment e.g. acrylonitrile, aclylic acid ester, caprolactam, CVL...

- Waste liquid from industrial waste disposal facility

- Waste liquid from desulfurization process such as STRETFORD, TAKAHAX and FUMAX.

Examples

Waste liquid and gas from agrochemical process

| Item | Waste oil | Waste liquid | Waste gas | |

|---|---|---|---|---|

| Capacity | 600kg/h | 700kg/h | 800kg/h | |

| High heating value | 42,000kJ/kg | 13,000kJ/kg | 4,000kJ/kg | |

| Operating time | 24 hours continuous | |||

| Combustion type | Submerged combustion furnace system | |||

| Combustion temperature | 1,200℃ | |||

| Exhaust gas residence time | 2 seconds or more | |||

| Combustion load | 38,000MJ/h | |||

| Exhaust gas flow rate | 30,000m3/h(NTP) | |||

| Effluent liquid flow rate | 2,000kg/h | |||

| Exhaust gas | Dust | 8mg/m3(NTP) or less | ||

| NOx | 500mg/m3(NTP) or less | |||

| SOx | 300mg/m3(NTP) or less | |||

| HCl | 70mg/m3(NTP) or less | |||

| Foot print | 35m × 30m × 20mH | |||