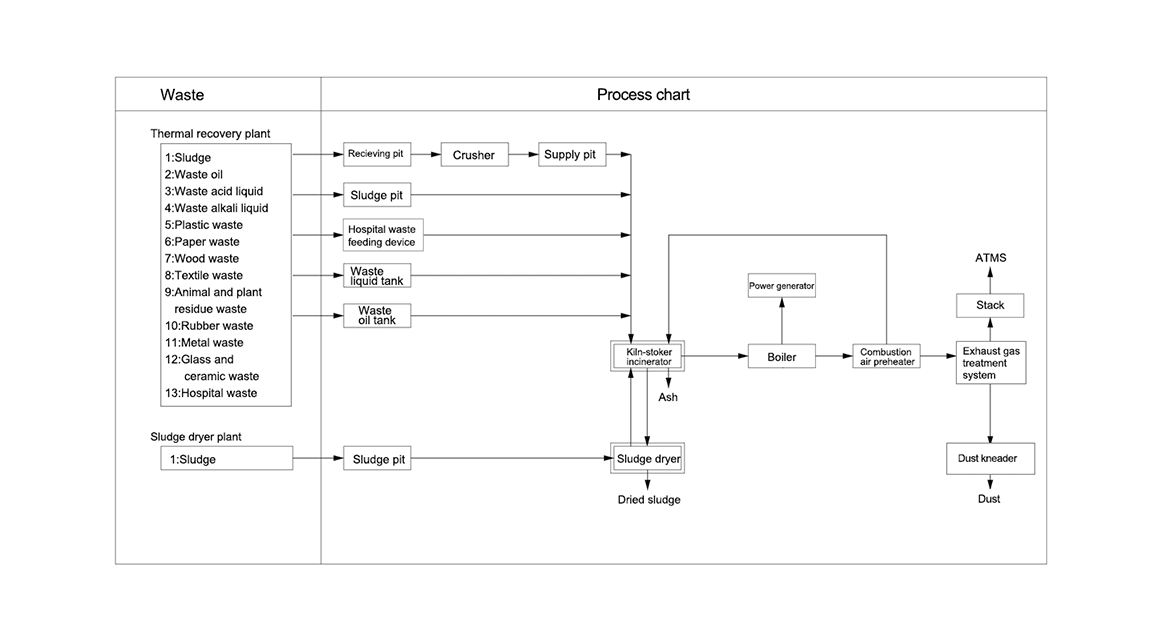

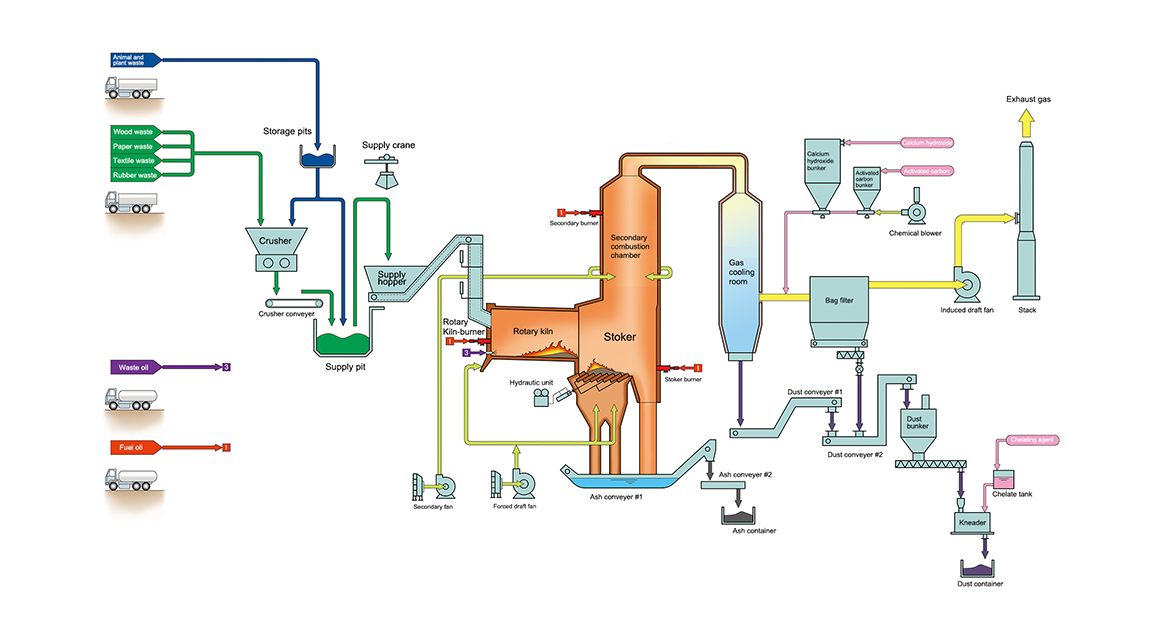

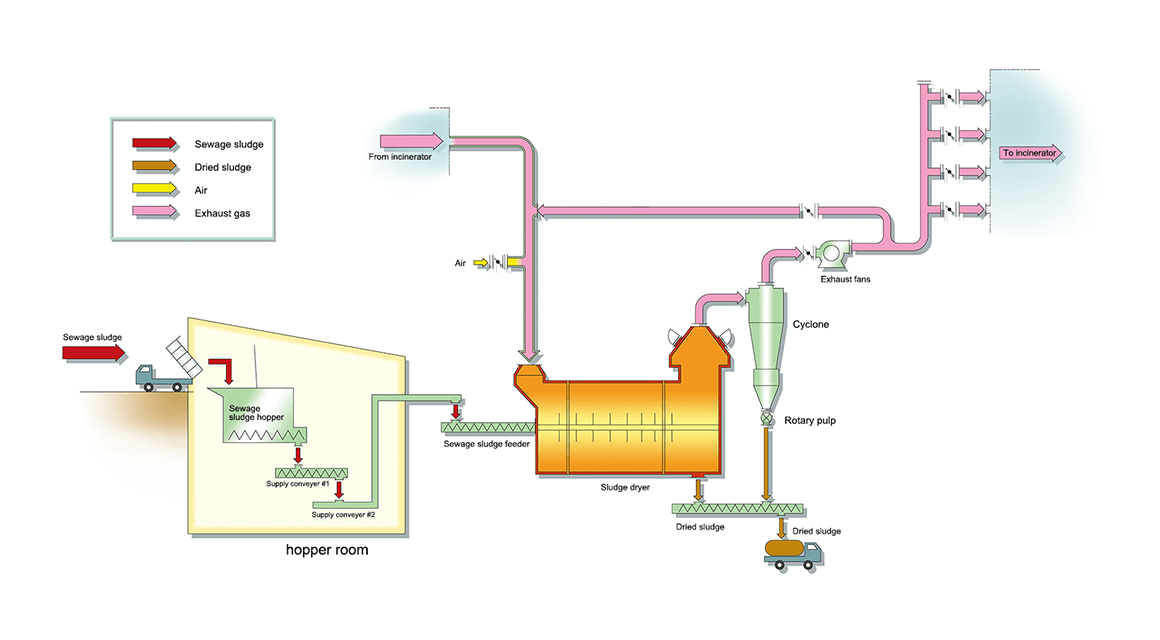

Solid waste incineration process

Rotary kiln and stoker system can treat many kinds of waste such as plastic waste, sludge and so on.

Features

- Treatment of various kinds waste

- Easy operation control

- Effective utilization of residual waste heat recovery (steam, power generation, preheated air, dry heat sources etc.)

Application examples

| Item | Elecltic appliance waste | ||

|---|---|---|---|

| Low calorific value | 14,000 kJ/kg | ||

| Capacity | 20ton/Day | ||

| Operating time | 24 hours continuous | ||

| Combustion type | Rotary kiln and stoker | ||

| Exhaust gas cooling type | Water spray type | ||

| Hazardous gas removal type | Bagfilter with lime and alkaline scrubber | ||

| Exhaust gas flow rate | 25,000m3/h(NTP) | ||

| Exhaust gas | Dust | 0.08mg/m3(NTP) or less | |

| NOx | 500mg/m3(NTP) or less | ||

| SOx | 300mg/m3(NTP) or less | ||

| HCl | 70mg/m3(NTP) or less | ||

| DXNs | 0.1ng-TEQ/m3(NTP) or less | ||

| Foot print | 50m × 25m × 25mH | ||