MIRAX

Process Overview

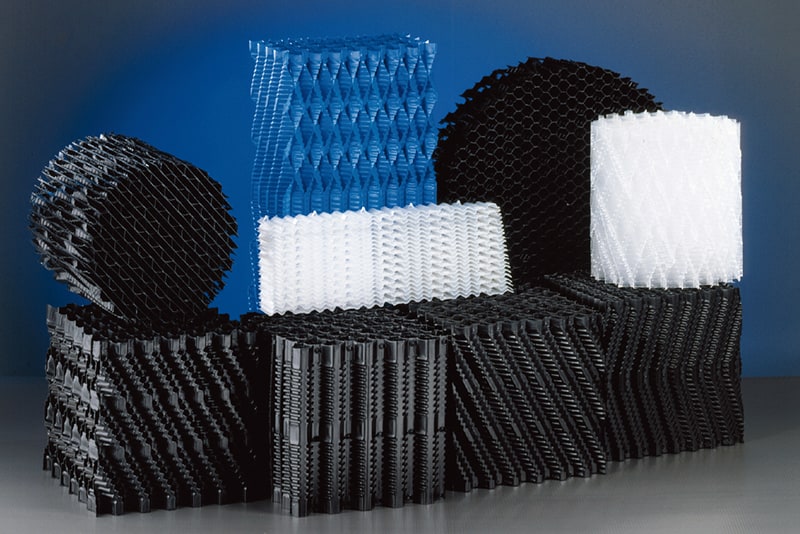

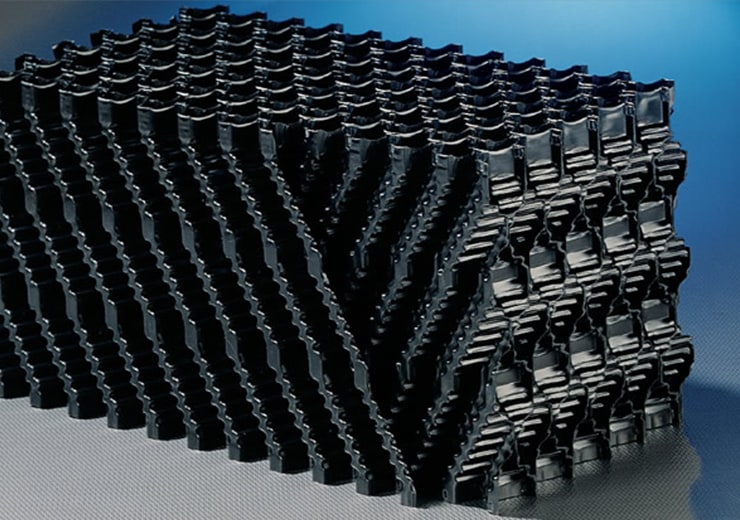

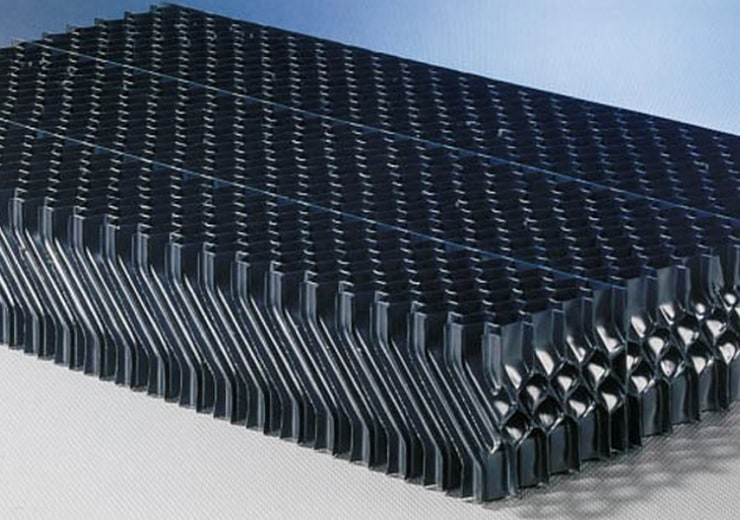

MIRAX is the regular structured plastic packing, applied to the mass transfers such as absorption, diffusion, distillation.

Originally, the random structured packings have been used as the plastic structured packings for mass transfer.

However, MIRAX is a brand-new type of the structured packings, which has the features of both the low pressure loss of structured packing and high corrosion resistance against the corrosive liquids such as acids and alkalis.

Features

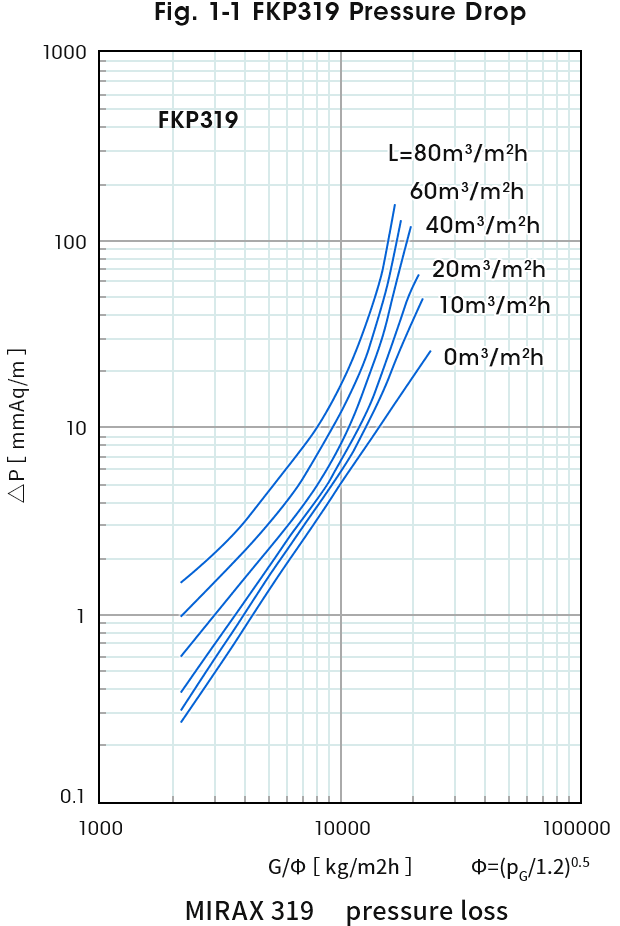

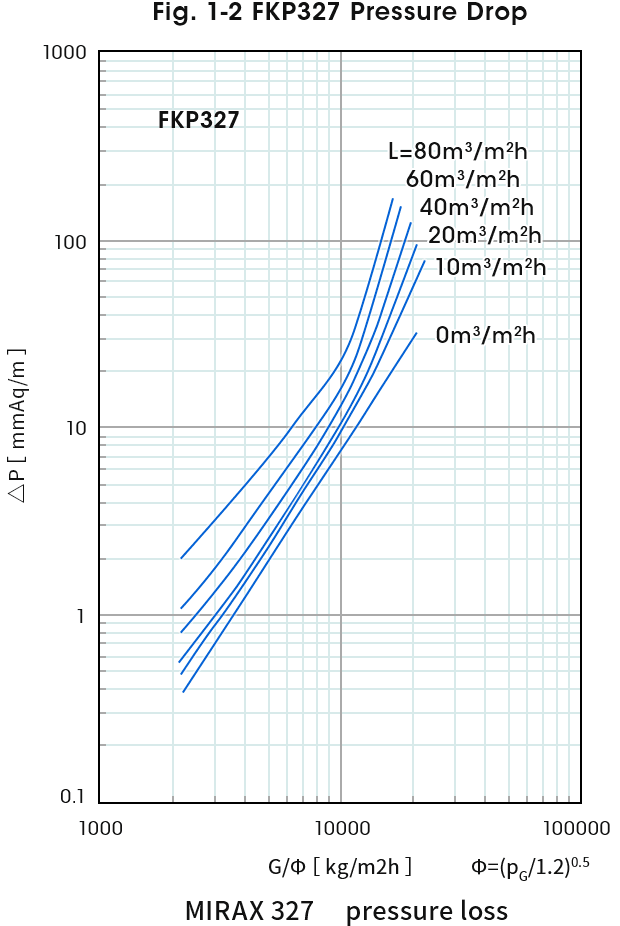

Low pressure drop

Pressure drop of MIRAX is less than half, compared to that of random packing with the same specific surface area.

Therefore, the throughput can be increased by replacing the conventional structured packings installed in the existing columns/towers by the MIRAX.

In case of the newly established columns/towers, MIRAX can reduce the diameter sizes of columns/towers.

(We calculate the throughput, column/tower diameters, etc. if the operation conditions are provided.)

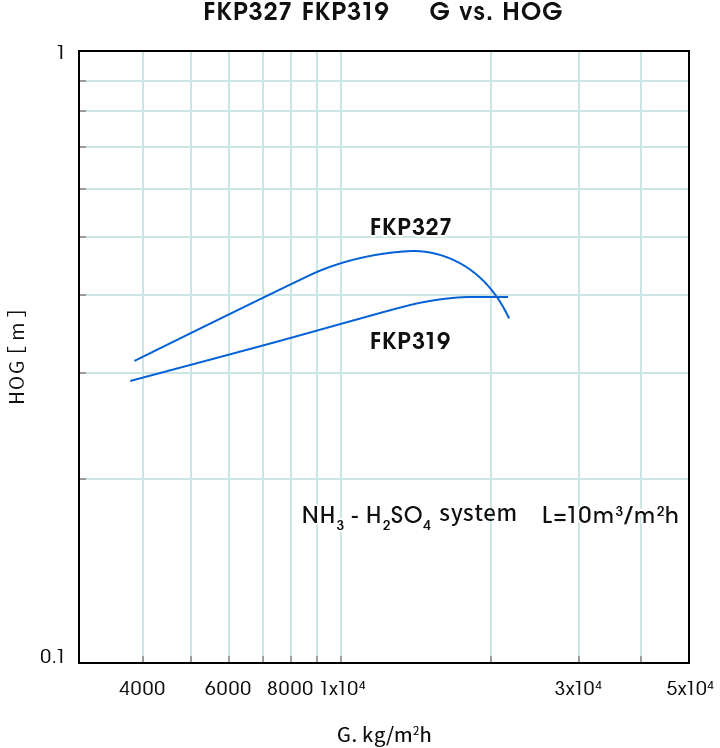

Superior mass transfer performance

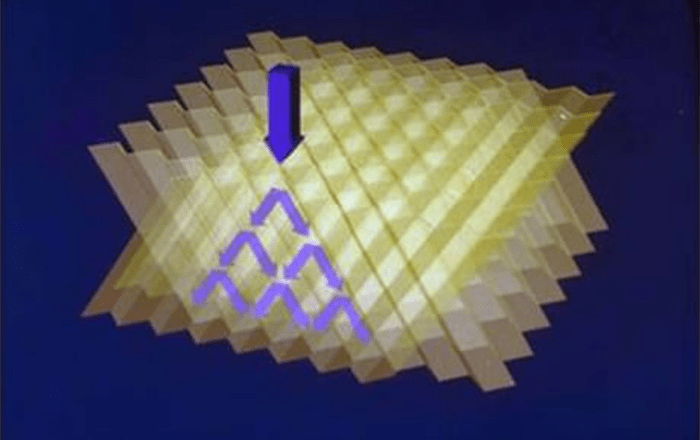

MIRAX has the superior mass transfer performance due to the surface finishing and a structure that reliably disperses liquids and gases.

The mass transfer performance per pressure drop of MIRAX is superior to the conventional random packings.

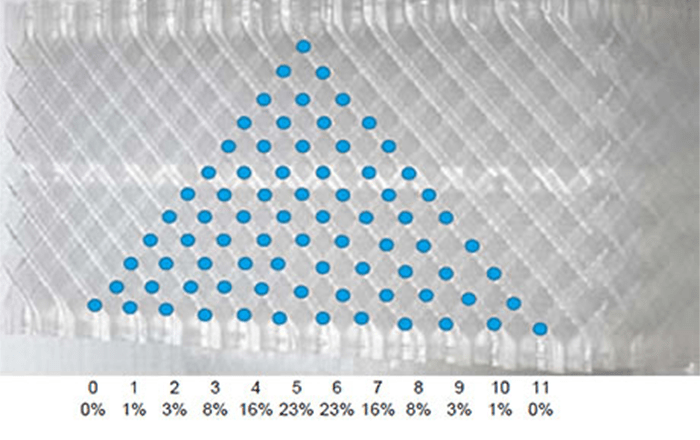

Superior liquid dispersal

MIRAX has superior liquid dispersal performance due to its proprietary structure.

Thus, no liquid re-distributors are required to be installed.

(Typically, no liquid re-distributors are required up to 8m).

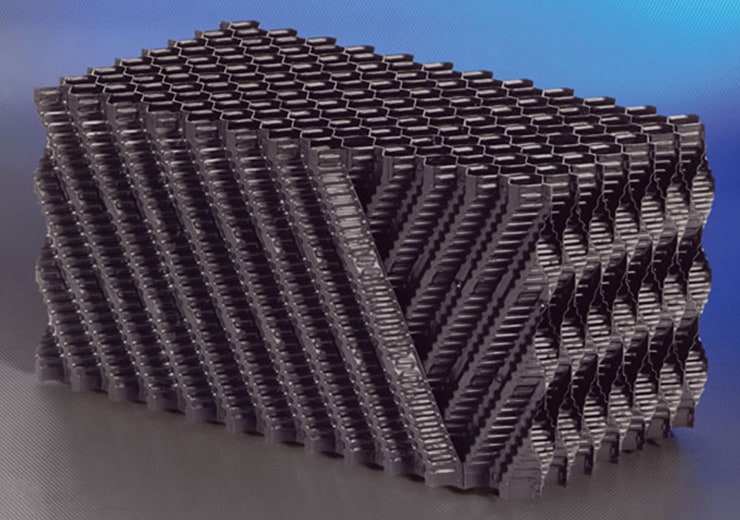

High buckling stregth

Since MIRAX is welded-structure, its buckling strength exceeds 5ton/m2.

Due to this high buckling strength, MIRAX can be used not only in the high-stacked conditions but also in the high liquid loads.

By changing the thickness of the structured packing in accordance with the operating condition, it is possible to reduce the volumes of the materials and also the costs.

Low cost

Since MIRAX is a welded structure, it is not affected by material properties in its manufacturing process, compared to that of the injection molded products.

MIRAX can be provided at a low price, that is proportional to the price of materials such as PVC and PVDF that are difficult to injection mold.

Product data

| Model | FKP 319 | FKP 327 | TEP 130 |

|---|---|---|---|

| Application | Mass transfer | Mass transfer | Demister |

| Surface area [ m2/m3 ] | 150 | 125 | - |

| Channel height [ mm ] | 19 | 27 | 18 |

| Maximum length [ mm ] | 2400 | 2400 | 2400 |

| Maximum width [ mm ] | 600 | 600 | 700 |

| Height [ mm ] | 300*1 | 300*1 | 125/250 |

| Material/heat resistant temperature | PP/80℃(Standard material) PP-HT/100℃ PVC/60℃ PVDF/120℃ |

PP/75℃ PVC/55℃ |

|

*1: Standard height is 300mm per layer. However, a layer with 600mm height can be also manufactured.